Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

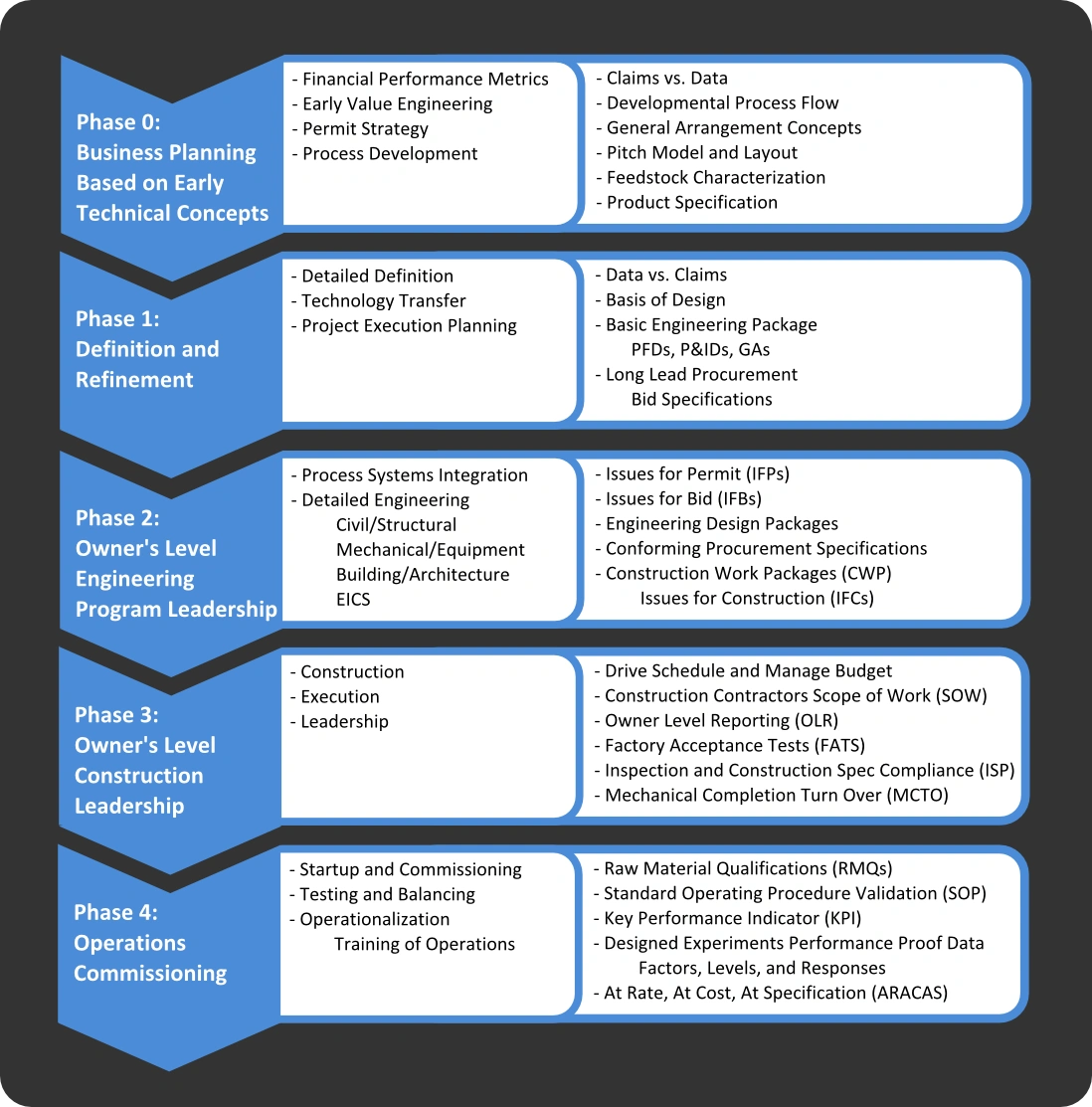

PreProcess leads projects. Leadership is the art of delivering what conventional management wisdom says cannot. PreProcess takes projects from idea inception through development, design, construction, and commissioning. We deliver fully operational systems producing product at rate, at cost, and at spec.

We use resources that respond and flex to the size of the project. We cover the needed services to deliver projects ranging from idea inception and patent art studies, to fuzzy front end definition of new technologies, to scale up and installation of first plant applications of client developed technologies, all the way through the build and operational normalization of the systems.

Check out our project leadership and project execution topics below:

To execute any project and organized and progressive development of detail is essential to making decisions based upon factual and accurate information. Simply, Front End Loading is an organized progression of staged gates that allow for metric evaluation against each stage’s criteria delivering actionable information to the expected level of accuracy as the decision-makers evaluate the on-going approval of the project.

FEL work flow is typically divided into three stages:

In every effort from fuzzy front end concept development to basic engineering packages, a series of iterative investigative learning events must occur. This is where the kernel or the idea for the technology and the project first emerges. These interactive learning opportunities better craft not only the technology but also the commercial opportunity.

To develop basic engineering packages including commitment grade cost estimates and the owner’s level project schedule for the detailed engineering, construction management, and operations commissioning we first engage in detailed learning and refinement of scope. This is commonly known as Phase 0 where activities include idea exploration, concept investigation, experimental data generation, proof of principle runs, and both individual equipment scale up and integrated system scale up.

In our experience, major inputs, outputs and conversion operations need to be characterized to insure success. Many times we have found that early project developments base financial and expected technical performance on claims that may or may not have valid data associated with the claim. We will present an analysis of the current state of the expected conversion parameter characterization then present a process development proof of principle plan to validate the claims or shore up the sections of run data that may need to be created to insure success of later phases of the project. This process development effort requires a separate proposal as many times the equipment trial runs and proof of principle experiments involve other not yet identified resources.

Usually the development of both the capital expenditure required (CAPEX) and the operating costs anticipated (OPEX) are one of the most debated issues in the early stages of a project. Many times numbers are forced to fit a certain expectation from past experience that may of may not be accurate depending upon the source and skill of the champion of the position.

Using industry definitions and the tools available in an organized and structured manner with clear definition in the accuracy and contingencies accounted for in the cost models leads to stronger financial understanding and more successful delivery of the project objectives. A cost estimate is also wrought with political positioning of the organization that may be presenting the results.

PreProcess follows the American Association for the Advancement of Cost Engineering principles and practices for developing cost estimates.

All projects have many stakeholders. The timely review, analysis and action taken keeps the design, construction and start-up efforts on track A road map is needed and leadership must be strong, decisive and clear on the expected progress against commitments. Open communication, factual data and a trust bond amongst the team members insures the most successful project.

Design reviews and the Process Hazard Analysis must be an iterative sequence. Started too soon, and the PHA will become ineffective. Begun too late, and the design costs and procurement process will incur change order costs. In the design work flow, the analysis of the constructability of a system is critical to keeping construction costs under control and the project on schedule. Many times constructability analysis can identify ways to reduce costs and drive the schedule to meet and beat the commitments need to keep the enterprise on track.

Each review needs to be scheduled on a pace to drive the iterative interactions required as information is derived from the sessions. Clear action deliverables with responsible parties hitting the needed dates is the project manager’s best tools from the team, kind of like a double play for a pitcher in baseball, a well-run design, construct and safety review work flow drives home the needed targets to meet the overall objectives of the effort.

Required deliverables at each design review stage against procurement, construction, and operations planning.

A traditional old school scale up thought is that systems should be run from front to back as a complete demonstration. This proves the scalability of the system. This old school method may give a false sense of security to any observer who has not completed the complex task of developing a new system. The principle of confounding interdependencies and the small system operating limit effects creates unresolvable inaccuracy in the understanding of the performance of the proposed system.

Emerging over the years an approach has developed that has been proven to be a more rigorous path to success. A complex system is decoupled and the unit operations that make up the system and are run individually using designed experiments that focus on the factors, levels, responses and constants of each unit at the boundary limits to insure that the confounding interdependencies do not hide a flaw in the system’s units.

The use of statistically based tools to understand the main effects of each characteristic of each unit provides independent information that drives the creation of meaningful correlations that enables the proper engineering of the system for integrated success.

Scaling systems is a necessary step in any project. Read more here:

The Testing and Balancing (TAB), Start Up and Commissioning Team, or simply the “TAB Team” focus is to remain nimble and responsive to the complex interdependent needs of the units during the testing, balancing, start up, commissioning and operationalization effort. The sequenced start up will be executed by the TAB Team. Performance metrics will be clearly defined and the effort is not complete until the TAB is no longer needed such that operations is fully trained and functional to maintain the defined performance.

The TAB effort begins with the Yellow Line Turn Over from construction which confirms that the equipment is installed and prepared for operations as defined by the engineering design. Motors are bumped and gear boxes are loaded with lubricants. A Pre-Start Up Safety Review is completed prior to any dry runs or loading shake down fluids. Daily planning meetings reviewing the detail of the day, and daily data review meetings use the facts from the process to determine any adjustments needed to the predetermined plan.

The effort uses a series of shakedown runs that will then evolve into designed experiments to develop the needed correlations and performance metric targets that enable the long term reliability in the performance overall system. The team uses Obvious At A Glance (OAG) information dashboards to keep communications simple and straightforward.

The ultimate operations philosophy is to use a “lights out” type of control room and allow most of the routine operations to be automated by locking the various algorithms and correlations in the process control system to keep a tight steady state operation enabling repeatable, reproducible reliability in product and operations.

PreProcess creates a startup and commissioning plan for every project execution. PreProcess also comes onto a project specifically for startup planning.

We have found over the years that permitting is one of the most intense and onerous areas of concern in any new chemical venture. It is common for the permitting to be on the critical path of many projects. Meeting the regulatory requirements on a chemical processing project can often be the largest driver of many aspects of many of the cost elements in the estimate.

The ultimate goal of the permit pursuit is to receive the “Permit to Operate” documentation from the various Authorities Having Jurisdiction (AHJ). This includes navigating many or all of the following:

On mega-project efforts we recommend that we partner with an environmental firm that is local to the site and would have expert experience in the local “personality” of the permitting process of the area.

Need help permitting a project?

Check out our article then give us a call.

High performance team members have specific roles and complementary talents. The team is committed to a common purpose, and works with a high level of collaboration. They are innovative, tight-knit, and built on trust. The team has the collective confidence to surmount any barrier.

Leadership is more orchestration bringing out and blending the subtleties of the common purpose of the team. As with all organizational structures, there is “the” leader shouldering the ultimate responsibility, however, everyone on the team is “a” leader. “Leadership” is rotated according to the need at that moment in time. Decisions are made on the analysis of the facts. Egos are checked at the door and there is efficient conflict resolution if it is ever needed. High performing teams could take over the world if that was the common goal to which everyone was committed.

A Process Hazard Analysis is a gathering of various design, construction, and operations stakeholders to objectively analyze a proposed design for the system. It is imperative that the participants are well prepared for the PHA. Much effort is wasted when the prerequisite information is not presented to participants with enough time to become familiar the system prior to the PHA.

PreProcess uses the PHA to insure the system has the highest level of safety and by using streamlining techniques and keeping the group on track with strong leadership, the effort is value adding and appreciated. Many times participants use the PHA to grind some ax or re-hash something that has already been established, the leadership of the PHA must keep ahead of the group and insure that no one person derails or hijacks the very important analysis for their own agenda. One technique to insuring a well-structured meeting is to insure that all required Process Safety Information is delivered and reviewed as a ticket to admission to the event.

PreProcess can also be hired to third party moderate PHA or PSM.

Process Safety Information (PSI) includes information pertaining to:

The Issue for Construction (IFC) document set is the product of detail design. These are the contractual documents that define all field effort. The IFC set must have rigorous control and distribution procedures to insure that the engineered design is what is actually built. The more simple and reduced the set of needed drawings to fully describe the system, the higher the probability of the project staying on budget. Over design and overlapping “turf” between disciplines creates confusion and complexity that is not needed on projects that are run with an expectation of efficient schedule and cost containment.

PreProcess has come into many projects, simplified many of the needed documents and applied the “less is more” principle to streamline understanding and effectiveness of the effort.

1. PFDs

2. P&IDs

3. General Arrangement and Layouts

4. 3D Model

5. Functional Requirement (FRED)

All technical and entrepreneurial pursuits live and die on clear communication. Many documents are created in any effort. The rule to live by is: less is more.

All documents should be simple in presentation and organization. The retrieval of the information must always point to the source. Specific information should reside in only one source. This is one of the most critical problems are project efforts expand. Poor communications and poor overlapping documents present conflicting information.

If the number of documents is simplified to the irreducible few, then the management of the versions of the paper copies and the electronic copies becomes paramount. Be careful of “Doc Control” software implementations. They usually come with a high activation energy.

Management of Change

This simple effort is also the basis for a strong Management of Change process. MOC is simply write down and communicate succinctly what you do, how it is to change, and keep it’s understanding by all up to date.

A megaproject is a high value, complex, interdependent, multi-organizational undertaking that creates a game changing difference in the landscape of chemical processing. The bonds that are formed, the lessons that are learned and the impact that is felt spans careers, industries and businesses. There is nothing more exciting.

Game changing mega projects are usually based upon some new process development that enables the cost optimization, capacity increase, or yield improvement on some needed chemical product. Feedstock changes, energy efficiency or new production routes are usually the chemical engineering technology behind a mega project.

A high performing megaproject team is built on excellence, confidence and passion. All team members must be comfortable with knowing that all members know how to execute as a team and not just as a group of people. Like a great shortstop and second baseman effortlessly turning double plays, each member of a high performance team knows that when they toss the ball their teammate will be there or as the member on the receiving end of the toss, they can make the play.

It is critical on a megaproject that the team dynamics are of support and continual improvement. Tasks are organized and decisions are made with the data that is available. Everyone can be everywhere. No single force of will can overcome the size of a megaproject. There is always a positive build of solutions from the ever present “can do” attitude. Needs are anticipated. Plans are built, but the act of planning is the important effort, not the plan itself. Goals are clear and the pathway forward may have multiple choices. The team is continually adjusting upward to become more effective, efficient and enjoyable.

Industrial Megaprojects are large, complex projects usually with a capital expenditure of $1 billion or greater.

The above engineering topics are a sampling based on common client questions.

While its best when we get involved early in the development stage to save on overall cost and timing, we are able to jump in at any point of the process.

We are equally comfortable in a lab, board room, or constructing in an operating plant. PreProcess leads the scale up, development, and commercialization of cutting edge technologies.

Direct: (949) 201-6041

Email: contact@preprocessinc.com

© 2010-2020 PreProcess, Inc. All Rights Reserved